The economics of recirculating aquaculture systems

Recirculating Aquaculture Systems (RAS) have become part of the global aquaculture landscape. Announcements of new, planned investments in large-scale RAS in countries around the world appear frequently in the aquaculture news media. Yet RAS, as a viable production system for aquaculture businesses, are not new. Blue Ridge Aquaculture Inc. (USA), for example, has been in continuous business for more than 30 years and is a clear pioneer and success story of a profitable, large-scale RAS farm. A few RAS farms have operated successfully in the United States for more than 15 years on a much smaller scale. Salmon smolt production in RAS has further emerged as a profitable sector in the salmon supply chain (Bjorndal & Tusvik, 2017 ). Less well publicized are other fish farming businesses that have incorporated RAS into their overall pond-based farming operations. In some cases, the RAS is used to grow fingerlings over the winter to a larger size for stocking into ponds in the spring to reach harvest size earlier in the year and extend the sales period for their crops. Other farms have installed RAS to produce specialty fish species that are sold at lower quantities but have high value in the market. Thus, there are proven examples of the profitability of RAS in global aquaculture.

What are new are the substantial investments in turn-key RAS facilities planned or proposed to operate on very large scales. While there are clear examples of profitable RAS-based businesses, many of the news stories continue to refer to the “unproven economics” of RAS. This editorial will attempt to break down what is known about the economics of RAS.

The press and those seeking venture capital for large RAS investments tout many advantages of RAS and often that RAS are the “future” of aquaculture. Chief among these claims is that RAS are more environmentally sustainable than other aquaculture production systems, and that a RAS facility can be located anywhere. Such claims are key to successful recruitment of venture capital, particularly the Environmental, Social, and Governance (ESG) capital that has been targeted by many RAS startup ventures.

Economics provides a lens through which to examine these claims. While economists use monetary values as a way to standardize discussion of relative quantities of inputs and outputs, at its most fundamental level, economics is “the study of scarcity, the study of how people use resources and respond to incentives…” (American Economic Association, 2023 ). After all, if a producer uses resources very efficiently, then the costs per unit of fish, shellfish, or shrimp associated with that use will be lower than if resources are used less efficiently. Thus, production costs per kg of aquaculture product are closely associated with the efficiency of resource use.

Are RAS more efficient than pond or raceway production of aquaculture crops? In terms of land, yes. RAS produce more kg of fish or shrimp per ha of land than pond or raceway production. Feed efficiencies also appear to be greater in RAS than in outdoor production systems because indoor production offers the opportunity for better control over temperature and water quality parameters year-round. Outdoor production is subject to fluctuating seasonal temperatures, losses to predatory birds and other animals, and greater challenges related to effective biosecurity measures in open environments. Individual ponds also exhibit a great deal of variability from one pond to the next even when treated in the same manner, with commonly measured coefficients of variation of 20% for key production parameters (Shell, 1983 ). Such variation results from ponds being plankton-based ecosystems that develop different plankton blooms in adjacent ponds and also because those blooms change over the production season.

RAS use resources other than land and feed less efficiently than other production systems. Energy use in RAS is high, although it is also variable (Badiola et al., 2018 ). Much of the relative energy use (and, hence, its cost) is related to the need for heating and cooling to maintain water temperatures in an optimal range for that specific species. Raising a tropical animal, such as tilapia, in northern climates will likely require more heating than raising tilapia in RAS in warmer climates. Similarly, raising a coldwater animal like salmon in a warm climate will likely require greater cooling in the building than raising salmon in a more northern climate. Thus, the climates of various locations will affect costs and, to some degree, limit where RAS can be located to be able to operate in an efficient and profitable manner.

Discussions of RAS frequently focus on the recirculating aspect of water use in the production tanks. Biofiltration technologies have become more efficient over time and have created the ability to recycle high percentages of the water used to produce fish/shrimp in RAS. Nevertheless, it has become clear that the total water use requirement of a large-scale RAS facility is quite high. Media reports and permitting applications for proposed RAS facilities have requested millions of liters of water (15–20 million liters/day) to be pumped into the facility daily with the same amount to be discharged daily. RAS facilities use water other than that used exclusively in growout, for purging off flavors, quarantining animals brought in from the outside, cleaning, processing, and when problems occur in the facility that require tanks to be emptied and refilled. The substantial water volumes required for large-scale RAS mean that RAS facilities cannot be located just anywhere—they must be located where there is access to the necessary volumes and quality of water required and where an acceptable (to the relevant regulatory authority) discharge system is either available or could be constructed.

RAS also discharge wastes, mostly in the form of sludge. While ongoing research seeks ways to utilize and recycle the sludge produced in RAS, most commercial RAS facilities in practice discharge sludge in traditional ways, often to a publicly owned or on-site treatment facility. Sludge disposal costs can be substantial and have contributed to the demise of RAS businesses.

RAS are also quite capital and labor-intensive. While not environmental resources, capital and labor are essential factors of production that are used intensively in RAS and account for some of the greatest costs in RAS production.

What is the economic bottom line for RAS? The answer is, of course, that it depends. The few long-standing RAS businesses have successfully developed and sustained business models over time that are profitable. The failure rate of RAS, however, is quite high. Comparisons of the costs, profitability, and resource-use efficiency across various production systems in the United States perhaps shed light on some key aspects and drivers of cost and profitability of aquaculture production in RAS as compared with that in ponds and raceways (Engle et al., 2020 , 2021 ). Other than land and feed efficiencies, intensive pond production of catfish (the most widely raised finfish species in ponds in the United States) uses capital, labor/management, water, and energy, capital resources much more efficiently, and at lower cost than RAS. Yield (kg/ha harvested from ponds and kg/m 3 harvested from RAS) is a major driver of costs in aquaculture because of the relatively high fixed costs associated with the facilities. The Engle et al. ( 2020 , 2021 ) studies used average yield values reported in the research literature from commercial farm datasets where possible. Overall, the RAS models were not profitable when all costs were accounted for. Substantial increases in yields of RAS over those used in the Engle et al. ( 2020 , 2021 ) analyses would be necessary to make more efficient use of energy, water, capital, and labor resources to reduce costs to a profitable level. Assuming that buyers will pay a premium price, especially for a business that projects high volumes of production, is not realistic. A few small-scale startup farms may be able to charge a premium price for a while, but only until other farms enter the sector with increased supply that drives market prices back to average levels.

Very high yields require high stocking densities, of course. Efforts have been made by animal rights groups to limit stocking densities of fish in net pens; yet stocking densities in RAS likely will need to be much higher than those in net pens for RAS to be profitable.

Are RAS profitable? Some clearly are, but many others have failed. As with any business venture, a key “resource” is the entrepreneurial ability of the owner to make correct choices with respect to the overall business model (i.e., scope, scale, engineering, species, targeted markets, specific products). Equally important is the skill of the manager who must make many decisions every day; the successful businesses are those with managers who make the correct decisions. High-intensity production systems like RAS require continuously high efficiencies in the use of the inputs that contribute the most to the per-kg cost of the product.

The key obstacle and challenge to the economic success of RAS is the need to increase the efficiency of use especially of capital (the greatest cost driver in RAS) and labor/management (the third greatest cost driver in RAS). Feed use in RAS is currently more efficient than in other production systems, but capital and labor/management are currently used less efficiently in RAS than in other production systems. The key technological development necessary to improve the economics of RAS is to increase the average (not the maximum ever achieved) harvested biomass per cubic meter of tank growout volume. Increased kg produced per cubic meter of tank production volume will reduce the capital and labor/management costs per kg of product sold. RAS can be profitable on a variety of scales if adequate attention is paid to the productivity of use of the capital invested in the tanks (that includes the associated filtration systems) and the use of labor/management by achieving greater harvested biomasses of product per kg of tank growout volume.

Is RAS the future of aquaculture? Terrestrial agriculture has diversified into indoor greenhouse and hydroponic production of various crops, but such diversification has complemented, not replaced, open field production of produce, grain crops, and livestock. Similarly, RAS is already part of the aquaculture landscape and will undoubtedly continue to be. Nevertheless, it is a highly intensive form of production that uses capital, labor, energy, water, and management in such an intensive manner that there is little room for incorrect decisions and mishaps when addressing the inevitable challenges that arise when raising a living aquatic organism. Research is needed to identify economically optimal yields, management strategies, scope, and scale of RAS as well as on more traditional pond, raceway, and net pen production of aquatic crops to provide comprehensive guidance to aquaculture producers and investors.

The Journal of the World Aquaculture Society welcomes research that focuses on commercial-scale production management strategies accompanied by detailed economic analyses to offer guidance to commercial aquaculture producers for all production systems.

- Google Scholar

- Web of Science® Google Scholar

About Carole R. Engle

Former JWAS Editor in Chief - Carole Engle has devoted more than 35 years to aquaculture research, extension, and teaching. In addition to publishing more than 110 scientific articles, four books, and more than 80 extension publications, she has a combined 49 years of editorial experience, including serving as Editor-in-Chief of Aquaculture Economics and Management. She has been honored with numerous awards from the U.S. Aquaculture Society, the National Aquaculture Association, the Catfish Farmers of America, and the Catfish Farmers of Arkansas. Engle was on the faculty of the University of Arkansas at Pine Bluff (UAPB) for more than 27 years and, as Director of the Aquaculture/Fisheries Center and Chairperson of the Department of Aquaculture and Fisheries, led it through a period of rapid growth, development, and expansion.

Gold Sponsors

Featured Store Items

Upcoming events, magazine articles, the many challenges of disease management in aquaculture.

Regardless of the aquatic species an aquaculture venture produces, there are significant risks to su...

JWAS Editor's Choice Awards 54(1)

Many challenges come with land-based finfish aquaculture. This study looks at water quality changes ...

A decadal outlook for global aquaculture

Feeding an expected global population of 9 billion by 2050 is a daunting challenge that is engaging ...

Recirculating Aquaculture Systems (RAS) have become part of the global aquaculture landscape. Announ...

JWAS Editor's Choice Awards 54(4)

This study assessed the suitability of partial or full (100%) replacement of fish oil (FO) with micr...

Shrimp farming advances, challenges, and opportunities

We have seen a significant growth of the shrimp industry over the last decade. Total imports in 2022...

JWAS Editor's Choice Awards 54(5)

This study provides an important assessment of unionized ammonia (NH3-N) and total ammonia nitrogen ...

- Agriculture Farming

- Livestock Farming

Project Reports

- Hydroponics

- Best Fertilizers

- Vertical Farming

- Sheep Farming

- Goat Farming

- Poultry Farming

- Fish Farming

- Pig Farming

- Dairy Farming

- Rabbit Farming

- Success Stories of Farmers

- Boost Fruit Yield

- District Wise Crop Production

- Schemes & Subsidies

- Agriculture Colleges

- Farm Insurance

- Disease Control And Management

Agriculture

Aquaculture

Horticulture

Agri Business

RAS Business Plan, Fish Farming Question and, Answers

Table of contents, what is a ras system in fish farming, how does a recirculating aquaculture system (ras) work, what are the ras system components, what are the benefits of the ras aquaculture system, what is the cost of ras fish farming, what are the types of recirculating aquaculture systems, what are the different constraints of ras, what is the difference between the ras and the biofloc system, explain about characteristics of recirculating aquaculture systems.

- Is RAS fish farming profitable?

How can you sterilize water in a RAS?

What is the main principle of the recirculatory water system, do hot water recirculation pumps save money, what are the advantages of the ras system, what are the different fish species in the ras system, what are the disadvantages of the ras system, conclusion of ras fish farming business plan.

Introduction to RAS fish farming business plan: Well, many people have many questions about RAS fish farming especially from set up to harvesting. We are putting these questions together and try to answer them in best possible way for RAS fish business plan. Proper RAS fish business plan will result in quality fish and higher yields with maximum profits.

Frequently asked questions about RAS fish farming business plan

Recirculation aquaculture systems (RAS) represent a new and unique method to farm fish. Fish grown in RAS should be supplied with all the conditions necessary to remain healthy and grow. They want a continuous supply of clean water at a temperature and dissolved oxygen content that is optimum for growth. A filtering or biofilter system is necessary to purify the water and remove or detoxify harmful waste products and uneaten feed. The fish should be fed a nutritionally-complete feed daily to encourage fast growth and high survival. RAS systems need a biological filter to process ammonia into nitrite, then nitrate.

In recirculating aquaculture, the culture water is purified and reused continuously. The steps in the RAS system include solids removal, ammonia removal, Co2 removal, and oxygenation. Recirculating aquaculture systems filter and clean the water for recycling back through fish culture tanks. New water is added to the tanks to make up for splash out and evaporation and for that used to flush out waste materials.

In case if you miss the Livestock Farming Business Plan .

A RAS is an almost completely closed circuit. The produced waste products; solid waste, ammonium, and CO2, are removed or converted into non-toxic products by the system components. Then the purified water is subsequently saturated with oxygen and returned to the fish tanks. By recirculating the culture water, the water requirements are limited to an absolute minimum.

Most RAS system contains a mechanical filter that removes solids and a biofilter that transforms ammonia and nitrite into less toxic nitrate; these can be separate components or combined into one unit. Systems use a sterilizer- type unit to reduce the numbers of microorganisms that cause disease, as well as some form of chemical filtration to help balance different compounds in the water.

- RAS system offers fish producers a variety of important advantages over open pond culture. This is a method to maximize production on a limited supply of water and land, nearly complete environmental control to maximize fish growth year-round, the flexibility to locate production facilities near large markets and convenient harvesting, and quick and effective disease control.

- RAS can be of various sizes ranging from large-scale production (over 1 million pounds per year) to intermediate-sized systems (500,000 pounds per year), to small systems (50,000 pounds per year). Then they can be used as grow-out systems to produce food fish or as hatcheries to produce eggs and fingerling sport fish for stocking and ornamental fish for aquariums.

- Recirculation systems in aquaculture have stirred a great deal of interest in the field of fish farming and expanding very fast globally. The flexibility to choose the scale and module is the greatest advantage of this system, where the entrepreneur can measure and control most of the production and marketing related variables. Wide range of design and site as per geo-climatic conditions and investment capabilities. It can be used in extreme weather zone with ease.

The minimum investment for a small RAS fish farming in India is estimated at approximately 4.8 lakhs for a tank measuring 1 cent. The price of the fish in the market is considered to be around Rs 250 per kg, mainly depending on the quality.

Recirculating aquaculture systems can be divided into five types;

- Hatchery and grow out – Hatchery and grow out systems house younger life stages, which are more susceptible to infections. They have high stocking densities and must allow for growth, increased size, and higher feeding rates over time. These systems house one (or just a few) species per system.

- Breeding – Breeding systems should be designed with specific reproductive sizes, behaviors, and social structure in mind.

- Long-term holding – Long-term holding systems, including quarantine systems, are designed to house older juveniles, sub-adults or adults for several weeks to several months. Feeding rates are lower than in grow out or breeding systems because these fish are no longer growing rapidly.

- Short-term holding – These systems are common in pet stores and live-market retail and wholesale operations. Fish are generally housed for 1 to 21 days. Holding tanks and filtration should be able to handle these wide variations.

- Display – Display farming systems are common in public aquaria, private businesses, and homes. For these display systems, water clarity is a primary concern. It should be managed with appropriate filtration and other means to reduce suspended particulates and discoloration.

Recirculation aquaculture system is essentially a technology for farming fish or other aquatic organisms by reusing the water in the production. The technology is based on the use of mechanical and biological filters, and the process can in principle be used for any species grown in aquaculture such as fish, shrimps, and clams, etc. The recirculation system is however primarily used in fish farming.

- High upfront investment in materials and infrastructure.

- Intensive technical monitoring of operations.

- An assured but limited supply of energy for operations and good water source, preferably borehole.

- Good fish feed quality, preferably high protein and fat extruded diets with high digestibility.

RAS systems need a biological filter to process ammonia into nitrite, then nitrate.

Biofloc system is used as a biological filter for some species. It is extraordinarily cheap to run as an aquaculture system but can kill the fish when it is not managed properly.

Water quality – The water in the system is recirculated through tanks and a series of water treatments to eliminate waste products. Unless the water is treated, fish will stress, resulting in retarded growth, increased predisposition to disease and lastly death. You must have a good general knowledge of the principles of water chemistry and a good knowledge of the biology of the species being cultivated.

You may also check the

Tanks – Production tanks change in size and shape. Smooth, round tanks with sloping bottoms are helpful as solids can be concentrated and subsequently removed from a center drain. This design facilitates thorough cleaning and ensures aeration is distributed.

Filters – In simple recirculation systems, water can be treated by two processes: mechanical filtration and biological filtration to remove dissolved toxic wastes.

Is RAS fish farming profitable ?

Due to lower sludge discharge costs and high fish density of the RAS system compared to traditional fish farming, RAS can fetch more yield of fish hence more profits.

Ultraviolet (UV) units and ozone are “sterilization” components that can be used “in-line” that means as part of the circuit or a side stream loop off the circuit to kill microorganisms in the RAS water.

In a RAS system, the water is treated continuously to remove the waste products excreted by the fish, and oxygen is added to keep the fish alive and well. A recirculation system is quite simple. Then, from the outlet of the fish tanks the water flows to a mechanical and biological filter before it is aerated and stripped of carbon dioxide and returned to the fish tanks. Therefore, this is the basic principle of recirculation.

Demand hot water recirculating systems can save water and also energy in some situations. Recirculation systems that operate continuously have the potential to use more energy, due to energy spent pumping and hot water energy lost from the water pipes, the energy saved by reducing hot water waste. When the water reaches the desired temperature range a control turns off the pump. This procedure is similar to turning on the hot water faucet and letting the water run until it gets hot, but instead of the water going down the drain, then it is simply returned to the water heater saving energy.

- RAS is an excellent use of technology to effectively manage water quality and fish welfare.

- RAS system is easier to control the effluents and waste produced and as a farmer has less volume of wastes to deal with.

- It is cost-effective for filtering and disinfecting farm water influents.

- RAS system can control diseases and ensures high degree Biosecurity.

- The system adjusts and controls production Feed Conversion Ration (FCR), Specific Growth Rate (SGR), Specific Feeding Rate (SFR).

- The low requirement of land and water as compared to the pond aquaculture system.

- Independence from the land-based large water source.

- Reduction in wastewater effluent volume and the ability to closely monitor and control environmental conditions to maximize production efficiency.

- Increased bio-security and ease in treating disease outbreaks if any.

- High output fish from a minimal area with fish density ranging up to 50 to 150kg/m3 under perfect conditions.

There are many advantages to using recirculation technology in fish farming . Though, one major aspect to be mentioned right away is that of diseases. The impact of pathogens is lowered considerably in a recirculation aquaculture system as invasive diseases from the outside environment are minimized by the limited use of water. Water for traditional fish farming is taken from a river, a lake, which naturally increases the risk of dragging in diseases. Due to the limited use of water in recirculation the water is taken from a borehole, drainage system or spring where the risk of diseases is minimal.

RAS systems are currently being used to grow catfish, striped bass, tilapia, crawfish, blue crabs, oysters, mussels, and aquarium pets. Indoor fish culture offer considerable flexibility to;

- Grow a wide diversity of fish species,

- Rear several different species simultaneously in the same tank (polyculture) or different tanks (monoculture),

- Raise a variety of different sizes of one or several species to another depending on market demand and price.

RAS systems allow growers to manipulate production to meet demand throughout the year and to harvest at the most profitable times during the year. RAS permits the grower to competitively respond to market price and demand fluctuations by altering harvest rates and times and species cultured.

RAS systems do have some disadvantages when compared to open pond culture. They are expensive systems to develop (building, tanks, plumbing, biofilters) and to operate (pumping, aerating, heating, lighting). Moreover, they are complex systems and require skilled technical assistance to manage successfully.

- The capital cost of starting a RAS is very high as compared to ponds and raceways.

- Operational cost is high due to electricity, oxygen inputs, and maintenance.

- Highly trained staff is required to monitor and operate the system.

- High investment at the beginning.

- Requires qualified personnel for the design and installation of the RAS system.

- The system requires skilled and qualified personnel for operating the farm.

If you plan well, the RAS fish farming is commercially viable and profitable. That’s all folks about RAS fish business plan. Don’t forget to comment. You may be interested in How to Earn Money from Rabbit Farming .

hi sir , i want details for RAS fish farming and project report

Hello sir, This prashanth.p from hyderabad …i have gone through your subject really amazing and very useful information. could you please share cost and profit analysis project report for tilapia, pangasius , carps, trouts and design of the RAS system. so that, it can be really helpful to me to start a fish production and also if possible can u please share cost analysis report for 3 variable tanks of 20000 liter capacity .. thanking you sir,

with regards prashanth

LEAVE A REPLY Cancel reply

Save my name and email in this browser for the next time I comment.

How to Make Houseplants Bushy: Effective Tips and Ideas

Innovative strategies for boosting coconut pollination and yield, pollination strategies for maximum pumpkin yield, the complete guide to chicken fattening: strategies for maximum growth, natural solutions for tulip problems: 100% effective remedies for leaf..., revolutionizing citrus preservation: towards a healthier, greener future, natural solutions for peony leaf and flower problems: 100% effective..., maximizing profits with avocado contract farming in india: a comprehensive..., natural solutions for hydrangea problems: 100% effective remedies for leaf..., the ultimate guide to choosing the perfect foliage friend: bringing..., from sunlight to sustainability: 15 ways to use solar technology..., the ultimate guide to dong tao chicken: exploring from history..., the eco-friendly makeover: how to convert your unused swimming pool..., mastering the art of delaware chicken farming: essentials for healthy..., 20 best homemade fertilizers for money plant: diy recipes and..., how to craft a comprehensive free-range chicken farming business plan, brighten your flock: raising easter egger chickens for beauty and..., how to optimize your poultry egg farm business plan with..., subsidy for spirulina cultivation: how indian government schemes encouraging spirulina..., ultimate guide to raising dominique chickens: breeding, feeding, egg-production, and..., borewell drilling cost, pump price, and pipe cost, polyhouse subsidy, cost, profit, project report, tractor subsidy, bank loan, eligibility, schemes, process, malabar neem project report details guide, cold storage project report, cost and subsidy, mushroom farming project report, cost and profit analysis.

Select Country

Asc international, asc belgium, asc netherlands, asc australia, asc germany, austria, switzerland, asc north america.

Aquaculture explained

Cooking with certified seafood.

Explained: What is RAS Aquaculture?

May 24, 2021

Aquaculture is an innovative industry – it doesn’t stand still for long. Fish farming has traditionally been done in either ponds or sea cages – in fact this practice goes back many millennia .

It is still the case that the vast majority of farms today are of this variety – what are sometimes known as net pen or semi-closed farming systems. But over the past few decades, as aquaculture has rapidly expanded to provide over half of the seafood consumed around the world, it has also frequently innovated and introduced new practices. One of these has been the introduction of closed systems – more commonly known as RAS, which stands for Recirculating Aquaculture Systems.

What are these systems? As you may have guessed from the name, they are sealed off from the environment and replace the natural flow of water in a sea or a lake with a water filtration and recirculation system. As a result, they can be placed on land – and if so they might be referred to as land-based farms.

Different Methods, Different Impacts

So is this a better way to farm? At ASC we don’t usually like to make sweeping generalizations, and won’t make an exception here because the fact is it depends on how a farm is managed. Closed, semi-closed, and net pen systems are simply different ways of producing farmed seafood and each has certain impacts that need to be managed carefully and responsibly. That’s where ASC comes in.

In the case of RAS, one of the benefits we have already mentioned is that there is more flexibility where a farm can be sited. Farms could be located closer to where consumers are, lowering the economic and environmental costs of transportation. But there is a flip side to that – in many areas or countries land and water are in short supply, so taking a farm out of the water and onto dry land can have other impacts and drawbacks.

Another potential advantage is that RAS farms greatly reduce the risk of escapes or disease transmission to wild fish population by tending farmed fish in a completely separate area.

On the other hand, there are certain areas where closed systems are likely to be more impactful. One example is energy use. Constantly recirculating and filtering water to ensure conditions remain right for the fish requires much greater energy than the natural flow of water utilized by pen systems. At a time when we are all thinking more about the carbon footprints of every aspect of our lives, including the food we eat, this is important to consider. It’s worth noting that even if farmed on land, seafood still has a low carbon footprint compared to most other animal protein and the energy source used by the farm, whether it is renewable or not, will make a big difference to its impacts. But this is still an impact that RAS farmers need to think about more than other fish farmers.

New ASC Requirements

While RAS farms still represent a small minority of the aquaculture industry, their use is growing. ASC works hard to reflect the always innovative nature of the industry by adapting its standards and program to reflect the most recent changes. For this reason, we have been working on new requirements that will apply specifically to RAS farms. While many of the impacts will be common to all aquaculture, issues like energy and water use, and effluent disposal, are different for RAS farms, so specific requirements are needed. Farms will need to meet these requirements in addition to the requirements in the relevant species standards –for example, a land-based seriola farm will be audited against the ASC Seriola Standard as well as the new module of RAS requirements.

Like all ASC requirements and updates, these have been developed with our stakeholders’ input and advice through an open public consultation. The feedback we have received has been used to finesse the requirements, which are now being finalized for launch.

The requirements are interim rather than permanent. Another recently concluded public consultation is looking at the environmental requirements of a new aligned Farm Standard . This will cover all ASC certified species, and will allow ASC to adapt the program efficiently to new developments while retaining the robust nature of the ASC standards. The Farm Standard will also integrate specific RAS requirements, so when this goes live it will replace these interim requirements.

In the meantime, ASC will continue to keep an eye out on the latest trends in aquaculture so that farms can be assessed on their individual performance against the most robust standards in the global aquaculture industry.

What is RAS?

Recirculating aquaculture systems (RAS) are a type of land-based aquaculture production platform utilized to raise a variety of aquaculture species, including Atlantic salmon, in a highly controlled environment.

Features include:

- Water reuse to minimize reliance on water resources

- Enhanced biosecurity—protecting fish from pathogens or predators

- Preventing escapees

- Protecting wild fish populations and surrounding environment (low to no impact)

- Local production—lower transportation costs/carbon footprint

- Control and collection of fish waste to reduce pollution discharge and recover nutrients

- Optimized environment for fish growth—control of temperature, water quality, feeds, and other environmental parameters

“RAS technology offers the ability to effectively capture and repurpose wastes—reducing environmental impact—to enhance biosecurity to prevent fish escapement, minimize pathogen entry or release to the surrounding environment, and highly control the rearing environment for increased fish performance and welfare. It also increases flexibility in site selection for proximity to markets. Farming fish locally to the market improves sales, reduces transportation costs, requires a smaller carbon footprint, improves traceability and product freshness, and supports the economy in local communities.”

–Steve Summerfelt, Chief Science Officer, Superior Fresh, LLC

For the first time, RAS is making it possible for Atlantic salmon to be a local, “farm to table” option on menus and store shelves that are far from ocean sources.

How does it work?

RAS requires specialized equipment and technologies designed to provide the fish with optimal water quality and control. A simple diagram by The Conservation Fund Freshwater Institute highlights general steps of RAS technology.

Step-by-step guide for RAS technology

Fish are grown and housed in tanks with special considerations accounting for their biological needs. The size, shape and construction of the tanks will differ based on species, biological needs, stocking rates, life stage, water supply, and the capacity of the entire RAS setup (size of pumps, biological filters, etc). Generally, round tanks which provide a double drain system for quick solids removal are recommended.

One waste product from fish is ammonia, which is dissolved in the water. Ammonia can become toxic and rapidly accumulate if not removed from water using biological filtration. The process of biological filtration cleans water at the molecular level using healthy, beneficial bacteria to transform toxic ammonia into other nitrogen-based compounds that are safer for fish. Nitrogen removal is the biological process by which bacteria convert the toxic ammonia to nitrate. Nitrate can also accumulate to toxic levels unless being removed via water replacement which is not desired in fully contained RAS farms. In such cases, nitrate is biologically removed by beneficial bacteria in another biological filter that converts nitrate into non-toxic nitrogen.

Each type of fish has a preferred temperature range based on its unique biology. Atlantic salmon, for example, are a cold-water species and can be sensitive to temperature changes outside of their normal ranges. Temperature is controlled using heating and cooling systems to guarantee that fish are held at their most optimal range.

Photo credit for header photo at top: Narayan Mahon, taken at the University of Wisconsin-Stevens Point Northern Wisconsin Demonstration Facility.

- Agriculture

Livestock Farming

Aquaculture

Poultry Farming

Recirculatory Aquaculture System (RAS) is a technology that efficiently uses water by recycling and reusing it after filtration. Unlike traditional aquaculture methods, RAS involves high-density fish culture in indoor/outdoor tanks, providing a controlled environment. Water is filtered and cleaned using mechanical and biological filters, with minimal new water added to compensate for losses.

Efficiently utilizing the system’s capacity is crucial for economic viability. The success of RAS depends on factors like feed quality, filtration type, and overall water quality. While large-scale RAS is capital-intensive, promoting Backyard Recirculation Aquaculture Systems can enable small-scale farmers and entrepreneurs in urban and semi-urban areas with limited land and water resources to engage in fish production.

The Recirculatory Aquaculture System (RAS) recycles and reuses water through mechanical and biological filtration processes. In RAS, water undergoes filtration to remove suspended matter, metabolites, excess nutrients, and solids, ensuring good water quality for the fish. This technology allows for high-density fish culture in tanks within a controlled environment, reducing the need for extensive land area.

Only a small amount of fresh water is added to minimize losses due to evaporation, splash-out, and waste removal. Less than 10% of the total water volume is typically replaced daily. RAS maximizes water efficiency while maintaining optimal conditions for fish growth and productivity.

In case you missed it: Project Report of Biofloc Fish Farming: Production Economics, Cost, and Profit Analysis

- Extended durability of tanks and equipment, resulting in long-term cost savings.

- Reduced dependency on antibiotics and therapeutic agents, leading to high-quality fish production.

- Lower direct operational costs associated with feed, predator control, and parasites.

- Potential elimination of parasite release into recipient waters, reducing environmental impact.

- Risk reduction from climatic factors, diseases, and parasites.

- Flexibility in a farm location, allowing proximity to markets.

- Capability to farm a wide range of species, regardless of temperature requirements.

- Improved feed management with 24-hour monitoring in RAS.

- Reduced stress on fish due to adverse weather, temperature conditions, pollution, and predation.

- Secure production of non-endemic species.

- Efficient utilization of water and land areas, promoting sustainability in aquaculture operations.

- A continuous and uninterrupted power supply requires backup electricity in case of power failures.

- The initial capital cost of establishing a recirculating aquaculture system is higher than traditional pond or raceway systems.

- Barramundi/Asian Seabass/Bhetki (Lates calcarifer)

- Cobia (Rachycentron canadum)

- Silver/Indian Pompano (Trichinotus Blochii/Trichinotus mookalee)

- Tilapia (Oreochromis niloticus)

- Pearl spot/Karimeen (Etroplus suratensis)

- Pangasius (Pangasianodon hypophthalmus)

- Rainbow Trout (Oncorhynchus mykiss) suits hilly or cold water regions.

They can thrive in high-density culture systems and exhibit good growth rates while maintaining water quality requirements. Barramundi, cobia, and pompano are popular for their taste and market demand. Tilapia is known for its resilience and adaptability. Pearl Spot and Pangasius are valued for their taste and fast growth.

Rainbow trout, with its preference for colder waters, is ideal for RAS in hilly regions. Choosing the right species for RAS is crucial for successful aquaculture ventures, considering market demand, environmental conditions, and the capability to thrive in a recirculating system.

- Insulated shed/building: A facility that serves as a store cum office for feed and accessories, as well as housing the pump house and other system components.

- Grow-out tanks: Circular cement or FRP tanks with inlet, outlet, and major drainage for rearing fish.

- Settling tanks: Used for separating sludge from the water.

- Water storage tanks: Sump tanks for storing water and overhead tanks for maintaining water pressure.

- Mechanical filters include drum and glass wool or muslin cloth filters to remove solid particles from the water.

- Pumps and motors: Essential for circulating and maintaining water flow within the system.

- Power generator: Provides backup electricity in case of power failures.

- Sludge collectors: Used to collect settable or dissolved solids.

- Biofilters and UV units: Help in the biological filtration of water to remove excess nutrients and maintain water quality.

- Electrification: The electrical wiring and connections required for the system.

- Automatic feeders: Used to automate the feeding process in certain cases.

- Aeration system: Provides air or oxygen to the water for maintaining proper oxygen levels and a carbon dioxide trapper system (degasser).

- Water testing kit: Used to monitor and assess water quality parameters.

- Water supply system: Includes sources like bore wells to ensure a continuous water supply.

- Inputs: This includes the necessary inputs such as fish seed, feed, additives, supplements, electricity or diesel for power, and human resources.

These components collectively create an efficient RAS setup, enabling the sustainable production of fish while maintaining optimal water quality and environmental conditions.

In case you missed it: Fish Farm Operations Management: Month-wise Maintenance for Better Profits

Proper feed management ensures the fish receive the nutrients for growth and development. Fish farmers can promote healthy growth, efficient feed utilization, and overall profitability in a RAS fish farming operation by using high-quality, species-specific feeds and providing appropriate feeding quantities and frequencies.

- High-quality feed: Use a high-protein feed that contains all the minerals and vitamins necessary for the fish’s nutritional needs.

- Species-specific feed: Different fish species have specific dietary requirements. It is important to choose feed formulations tailored to the specific cultivated species.

- Feeding quantity: Feed the fish at a rate of 3-5% of their body weight, depending on the quality and protein content of the feed. Adjustments can be made based on the growth and appetite of the fish.

- Feeding frequency: More frequent feedings, preferably several times daily, can lead to better growth rates and improved feed conversion ratio. Regular and consistent feeding schedules are essential for optimal fish growth and health.

Project Report of RAS Fish Farming

- Initial Investment: The cost of setting up a RAS fish farm can be higher compared to traditional pond-based systems due to the infrastructure required, such as tanks, filtration systems, and electrical installations.

- Operational Costs: Operating a RAS fish farm involves expenses like feed, electricity, water, labor, maintenance, and periodic equipment upgrades. These costs can differ depending on the scale of the operation and the species being cultivated.

- Revenue Generation: Profitability on a RAS fish farm comes from selling the harvested fish. The market demand, selling price, and production volume are crucial in determining the revenue potential.

- Risk Management: Like any business venture, RAS fish farming involves risks like disease outbreaks, market fluctuations, and environmental challenges. Adequate risk management strategies should be in place to mitigate these risks.

- Project Viability: Conducting a thorough project report is crucial for assessing the financial viability of a RAS fish farm. It involves estimating costs, projecting revenues, and conducting a comprehensive analysis to determine profitability and return on investment.

In case you missed it: A Guide to Sustainable RAS Fish Farming Practices

The cost of production at a RAS (Recirculatory Aquaculture System) fish farm, specifically for Nile Tilapia (GIFT), involves several components.

- Tank Size and Volume: The fish tanks used for Nile Tilapia (GIFT), in this case, have a size of 6.7m x 6.7m x 2m, with a total volume of 90 m3.

- Stocking Size and Density: Fingerling-sized Nile Tilapia (GIFT) with a stocking density of 6000 fish per tank.

- Survival Rate : A survival rate of 90% of the stocked fish survives throughout the culture period.

- Feed Conversion Ratio (FCR): The feed conversion ratio is 1:1.3, indicating that it takes 1.3 kg of feed to produce 1 kg of fish.

- Culture Period: T he culture period or crop duration for Nile Tilapia (GIFT) is six months.

- Cost of Seed and Feed: Each fingerling (seed) costs Rs. 4, while the feed cost is Rs. 30 per kilogram. The total feed required for the culture period is estimated to be 3.51 metric tons (MT).

- Size at Harvest and Expected Biomass: Nile Tilapia (GIFT) is expected to reach a size of 500g at harvest, with an estimated total biomass of 2.7 MT.

- Sale Price: The expected sale price for Nile Tilapia (GIFT) is Rs. 140 per kilogram.

In case you missed it: Sustainable Fish Farming: Zero Waste Fish Farming Practices

- Total Capital Cost : Rs. 1.75 lakh + Rs. 5.00 lakh = Rs. 6.75 lakh

- Total Input Cost : Rs. 0.20 lakh + Rs. 0.82 lakh + Rs. 0.10 lakh + Rs. 0.45 lakh + Rs. 0.10 lakh = Rs. 1.67 lakh

- Total Cost (A+B): Rs. 6.75 lakh (Capital Cost) + Rs. 1.67 lakh (Input Cost) = Rs. 8.42 lakh

- Total Cost (A+B) : Rs. 8.42 lakh (Capital Cost + Input Cost)

- Gross income from the 1st crop : Rs. 4.78 lakh

- Gross income at the end of the 1st crop after deducting recurring cost for the 2nd crop : Rs. 3.28 lakh

- Gross income from the 2nd crop : Rs. 4.78 lakh

- Gross income at the end of the 2nd crop : Rs. 11.06 lakh

- Depreciation cost at 15% of the capital cost: Rs. 0.90 lakh

- Net Profit = Gross income – Total Cost (A+B) – Depreciation cost

- Net Profit = Rs. 11.06 lakh – Rs. 8.42 lakh – Rs. 0.90 lakh

- Net Profit = Rs. 1.74 lakh

Net Profits indicate that the RAS Fish Farm has shown profitability and economic feasibility, with a positive net profit. Costs May vary depending on market conditions, operational efficiency, and other production costs.

Submitting the Project Report (PR): The beneficiary must submit a project report and required documents, including proof of land availability (owned or registered lease document), to the concerned District Fisheries Office for further processing. In the case of leased land, a registered lease document for seven years from the submission date of the Self-Contained Proposal is required.

Self-Contained Proposal (SCP): The beneficiary must prepare a Self-Contained Proposal with full justification and technical-economic details, including the species/variety to be cultured, capital cost, and recurring costs involved. The project report should also provide information on anticipated employment generation, fish production enhancement, specific project implementation timelines, etc. This proposal needs to be furnished to the District Fisheries Office.

Restriction on Governmental Assistance: Governmental assistance for subsidies will be limited to one large, one medium, or one small RAS unit for an individual beneficiary. For a group of fishers and fish farmers, assistance will be limited to two large, three medium, or four small RAS units per group or society. However, a cluster or area may have multiple groups or societies. The concerned authority will decide the implementation modalities and upper ceiling for total eligible area support for FFPOs/Cs.

In case you missed it: Fish Hatchery Business Plan: How to Start, Cost, Profits, and a Great Way to Make Money

Availing subsidies for RAS fish farming requires proper documentation, including the project report and justification for technical and economic aspects. The restrictions on governmental assistance aim to ensure the equitable distribution of subsidies among beneficiaries. It is important to adhere to the guidelines and procedures set by the District Fisheries Office and other relevant authorities to avail of the subsidy successfully.

Conducting a cost and profit analysis for a RAS fish farm is needed to assess the venture’s economic feasibility and profitability. A well-prepared project report and accurate financial evaluation are essential for making informed decisions and maximizing returns.

Pig Fattening Essentials: From Selection to Sale for Beginners

Raising wagyu cattle: a complete guide for premium beef production, soil types and their water holding capacity, optimizing irrigation schedules for coconut groves for enhanced yield, espresso your garden: coffee grounds for healthier acid-loving plants.

- The Best Soil Mix for Snake Plants: How to Mix Your Own Snake Plant Soil

- Green Thumb Success: Expert Tips for Cultivating Greenhouse Beans All Year Round

- Bloom All Year Round: The Ultimate Guide to Indoor Hyacinth Care

Eco-Friendly Gardening: How to Make Liquid Fertilizer from Kitchen Waste

- Ultimate Guide to Grow Anise in Pots: Explore Seed Propagation to Harvesting

- Guide to Raising Chester White Pigs: Discover Breed Facts to Growth Management

- Mastering the Elegance: The Ultimate Guide to Weeping Cherry Tree Care, Planting, and Maintenance

- Ultimate Guide to Planting Garlic in Grow Bags: Growing Strategies for Beginners

- How to Fix Spider Plant Leaf-Related Problems: Natural and Organic Remedies

- 10 Reasons Why Your Tulsi Plant is Shedding Leaves: Home Remedies and Solutions

- Optimizing Growth and Yield: The Advantages of Palm Bunch Ash Fertilizer

Utilizing Neem Oil Extract as a Natural Pesticide for Hydrangea

- From Soil to Harvest: Various Ways in Which Farmers Can Use AI Tools

Steps to Encourage and Induce Citrus Flowers: A Comprehensive Guide

- How to Fix Snake Plant Leaf-Related Issues: Natural and Organic Remedies

- Transform Your Garden into a Fragrant Oasis with Raat Ki Rani (Night Blooming Jasmine)

- Discover the Ideal Chicken Breeds for Philippine Farms

- How to Create a Poultry Egg Farm Business Plan for Profits

- Grow Lemon Cucumbers Like a Pro: Insider Techniques for Bountiful Yields

- Ultimate Guide to Caring for Your Pink Princess Philodendron: Tips for Thriving Variegation

- Areca Nut Profit Per Acre: Calculating Yield and Cost of Cultivation

- How Kaveri Chicken is Becoming a More Profitable Breed in Indian Backyards

- Transform Your Barn: 9 Steps to Convert a Horse Stall into a Chicken Coop

- Exploring Suffolk Sheep Disadvantages with Limitations and Challenges

- Guide to Solving Potted Lemon Tree Problems: How to Revive Lemon Tree in Containers

- Steps to Encourage Female Pumpkin Flowers: Best Strategies for More Flowers and High Yields

- Ultimate Guide to Yellow Raspberries: Exploring from Planting to Care

- Ultimate Guide to Planting Ginger in Grow Bags: Growing Strategies for Beginners

- Ultimate Guide to Growing Red Creeping Thyme: Propagation, Planting, Pruning, and Care

- Top 10 Common Peacock Plant Problems and How to Fix Them

- Ultimate Guide to Raising Naked Neck Chickens: Feeding, Egg-Production, Breeding, and Care

LEAVE A REPLY Cancel reply

Save my name and email in this browser for the next time I comment.

The Best Soil Mix for Snake Plants: How to Mix...

Green thumb success: expert tips for cultivating greenhouse beans all..., bloom all year round: the ultimate guide to indoor hyacinth..., ultimate guide to grow anise in pots: explore seed propagation..., guide to raising chester white pigs: discover breed facts to..., mastering the elegance: the ultimate guide to weeping cherry tree..., ultimate guide to planting garlic in grow bags: growing strategies..., how to fix spider plant leaf-related problems: natural and organic..., 10 reasons why your tulsi plant is shedding leaves: home..., optimizing growth and yield: the advantages of palm bunch ash..., from soil to harvest: various ways in which farmers can..., how to fix snake plant leaf-related issues: natural and organic..., rice production in myanmar; paddy farming in myanmar, banana farming information guide, growing oats information for beginners, contract goat farming in india: how to earn an extra income from this long-term investment, chilli cultivation information guide, how to start and succeed with microgreens business plan.

- Magazine + Enews

- Floaters & Sinkers

- Fresh Water Fish

- Salt Water Fish

- RASTECH 2020 Conference

- RASTech Magazine

- Hatchery International

- Virtual Events

- WINAA Summit 2023

- WINAA Summit 2022

Information

- Digital Edition

- Digital Edition Archives

- eNews Archives

United States’ RAS sector gets a leg up

February 23, 2021 By Liza Mayer

A consortium of experts that aims to advance the United States’ fledgling RAS salmon industry has officially launched and its website is now live.

The Recirculating Aquaculture Salmon Network (RAS-N) comprises institutes and private sector entities that will look into role of recirculating aquaculture systems (RAS) in addressing US seafood deficit.

They plan to identify technological and scientific gaps and prioritize research that will help advance industry development. Those efforts will be published in the RAS-N’s website at www.ras-n.org.

A $1.2-million grant from NOAA’s National Sea Grant Office in October 2019 got the initiative started.

Maryland Sea Grant and University of Maryland, Baltimore County, are lead partners in the initiative. Industry collaborators, which matched the fund from NOAA, include Superior Fresh, Whole Oceans and Riverence.

“Together, the private and public sector have invested more than $2 billion into land-based salmon aquaculture, and its technologies and knowledge base are rapidly advancing. Our partners and collaborators represent a broad approach in nurturing and supporting sustainable, land-based RAS Atlantic salmon production in the United States,” said RAS-N.

Advertisement

- USDA funds development of fish-free feed for rainbow trout

- Fish-free tilapia feed breakthrough

Marine Ecological Field Methods: A Guide for Marine Biologists and Fisheries Scientists

Medaka: Biology, Management, and Experimental Protocols, Volume 2

Recent Advances in Micro- and Macroalgal Processing: Food and Health Perspectives

Fisheries and Aquaculture: The Food Security of the Future, 1st Edition

Diatoms: Fundamentals and Applications

Clinical Guide to Fish Medicine

Designing Recirculating Aquaculture Systems

This self-paced course explains the basic engineering principles behind a successful recirculating aquaculture system (RAS) design. The objective of this course is to provide sufficient information so that you will be able to design, construct, and manage your own RAS system.

Dr. Timmons

Course description.

This self-paced course explains the basic engineering principles behind a successful recirculating aquaculture system (RAS) design. The objective of this course is to provide sufficient information so that you will be able to design, construct, and manage your own RAS system. Basic principles of business management and securing investment capital for the small family farm will also be reviewed. At the conclusion of the course, you will have received the essential information necessary to design your own system and have a fundamental knowledge of the principles influencing the numerous design options.

Course Includes:

- 14 modules.

- 11+ hours of video lectures.

- Reading assignments.

- Self-check quizzes

- One design workbook

- One final assessment

- Extensive supplementary videos

Topic Covered:

- Overview of recirculating aquaculture systems (RAS) engineering

- Water quality objectives, monitoring and measurement

- Fish growth and system staging

- Engineering design of individual unit processes

- System management

- Fish health management

- Economic and risk evaluation

After completion you will be able to:

- Examine how to design a recirculating aquaculture system, component, or process to meet production objectives

- Determine how to best select appropriate water quality targets

- Develop a capability to design pumping systems

- Build an analytical capability to quantify costs of production

- Identify the critical factors for managing a fish farm

Who should enroll:

- The course is structured to be relevant for a wide range of student experiential levels, from novice to expert. Course expects no prior knowledge, but some background in aquaculture is always helpful. The course textbook provides more in depth treatment on a variety of the topics and there are references as well on individual topics at the back of each book chapter.

- Individuals considering starting an indoor recirculating farm and at all stages, e.g., planning stages, early years of operation, and expansion of current operations

- Consultants to the industry

- University and high school teachers that include an aquaculture component in their classes

- Entrepreneurs

- People (aquaculturalists) currently managing flow-through systems

Instructor:

Dr. Michael B. Timmons.

Michael Timmons is a Professor Emeritus & Graduate Professor in the Department of Biological and Environmental Engineering at Cornell University.

His program is centered on entrepreneurial-driven enterprise. He provides a foundation of information related to the production of aquacultured products, both fresh and saltwater, with an emphasis on sustainable and environmentally friendly engineering technologies. He works with private industry to improve technology of water recirculating systems for producing fin and shellfish. Each year for the last 15 years, he conducts a 1-week long short course on the principles of recirculating aquaculture.

Watch the First Module Below!

Introduction to World Aquaculture

Watch Fish Production Designing Recirculating Aquaculture Systems

The Importance of Sustainability

Benefits of Recirculating Aquaculture Technology

Economic Drivers to Consider Designing Recirculating Aquaculture Systems

How to Compete in Seafood Markets

Slide: 1-PTRRAS001_M1_introduction-to-world-aquaculture

Transcript:

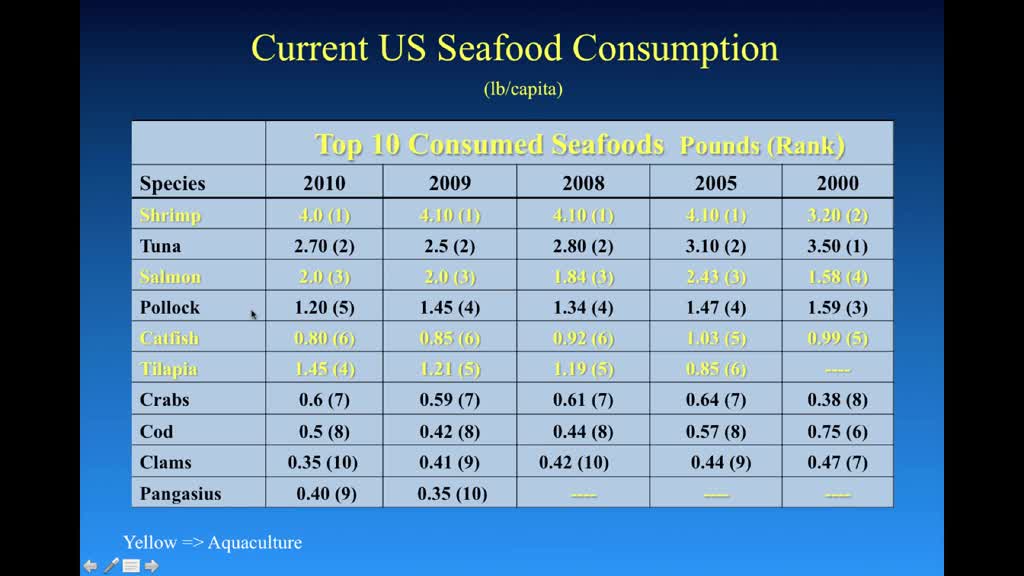

Welcome to the first module in the first section of recirculating aquaculture systems. By the way, here is an important acronym. That’s called RAS, R-A-S. So, maybe you can RAS people now. Okay. So, we’re going to go to our first slide which is here. Okay. So, part of this introduction is to give you some reasoning and possibly why you should be excited about even thinking about studying the subject in the first place. And that is because some of the statistics here. Okay? What are they? Seafood provides essential nutrition for over 1 billion people. Two, more than 37% of the world’s fish production is traded internationally. Three, seafood is the most globally traded protein of all the commodities. Beef, pork, chicken, lamb, etc., etc. It’s the most highest volume of all those different commodities. Next, the value of the fish trade exceeds international trade and all other animal proteins combined. 75% of our fisheries are considered to be fully or overly exploited. Wow. That they’re overexploited, yeah, that means they’re not there and where is the fish going to come from to feed all these people? Okay. Next point, more than 50% of all food fish supply comes from aquaculture. Wow. 50% of all the fish are coming from aquaculture at this point as opposed to what we call wild catch, what you traditionally think of where seafood comes from. People going out boats and nets and things like that but 50% of all our seafood right now comes from aquaculture. When I started in this subject 30 years ago, that number was like 5%. So, dramatically increasing. Aquaculture should be surprising. Aquaculture is the fastest growing food production system currently in existence. 8% annual growth. Okay. Are you excited? I hope so. So, look, here’s that statistic I showed you about where the seafood is coming from. Looking out here 2015, you can see about half of it is from aquaculture. There is some distinction people make

between aquaculture product going into the food market versus fish products that go into the animal feed markets. So, about a third or so of the wild catch goes into fishmeal. Okay? So, when you subtract that off, then the aquaculture component is actually more than 50% of the wild catch component. Okay? And then you see the little red line here going up. I forgot I had this cursor and show you going up and up and up and up and up. Right? We’re going to have seven or eight, nine billion people by 2050. Right now, we’re at seven, six and a half billion, just keeps going up. And as the economies improve, which they are worldwide, that means their ability to buy higher value products i.e. proteins, meat proteins also increases. Okay. Next slide. Okay. Well, what kind of seafood do we consume? Okay. And you look across the top here. Here it states. Things haven’t changed too much. Shrimp is number one and salmon and tuna and tilapia down here so look. So, I got these things numbered now. So, one, two, three, four, five, six. Again, here’s something very interesting. Tilapia in the mid-90s, this was zero. Okay. So, tilapia has made huge inroads into supplying part of that seafood demand. The commodity products here in yellow represent aquaculture. Okay? So, yes, aquaculture. Future of marine fisheries, well, they’re in trouble. Marine fisheries is 25% of the world marine resources are overexploited. 30% of our migratory animals are under severe pressure. It’s a problem and it is actually is kind of interesting. One thing is that the Earth is two thirds covered with water but there’s not much of that water that’s actually productive for growing fish or supporting seafood life. There’s only a few hundred miles from each of the shores. So, that’s pretty much why we’re at a steady state value in terms of what the oceans are producing. So, that 90 million metric tons as a reference point. And now, we produce about 90 million metric tons of seafood product. So, here’s where the gap starts to be pretty evident. Our current world population is about six and a half billion people, by 2050, 9 billion which gives us what? An 84 billion pound gap in the need for seafood product. Where is that going to come from? Well, that’s why you’re taking the course because we think with good evidence that that is all going to come from aquaculture and you’re going to learn about recirculating aquaculture because it conserves It’s the most sustainable form of aquaculture. Okay. Here, it shows you these supplies, what was happening. So, the wild catch you see, you get different numbers here but it’s somewhere around 100 million metric tons, 90 million metric tons and with good management, we think we might be higher but this is probably an overestimate. Aquaculture keeps popping up, going up up up up up. Okay? And our percentage is about 50% at this point. Okay. So, the per capita and important number for you to realize is per capita consumption, that’s about worldwide, we think is probably in the 17. This is kilograms so it’s about 17 or 38 pounds. This is per capita and that’s an interesting number in itself because some countries, say Japan for example, might be 100 kilograms per capita and other countries might be two or three. My belief is that given a well-priced or competitively priced product against the other meats, people will choose seafood. Anytime you see numbers that are less than 15 or 20 kilograms per person for that particular country, that means there’s a lot of opportunity. Okay? Where

are these fish going to come from? Well, relative to the U.S., we import almost all of our fish. Most of these fish, the supply is going to come from low-income countries where labor and environment where regulations tend to be less stringent. The environment is going to be a concern. Are these countries able to supply products to western countries where environmental issues are of a concern, versus, just simply price. And why is it that the U.S. can’t compete? Well, maybe it’s because our products cost too much. Okay. That wraps that one up folks.

Slide: 2-PTRRAS001_M1_fish-production

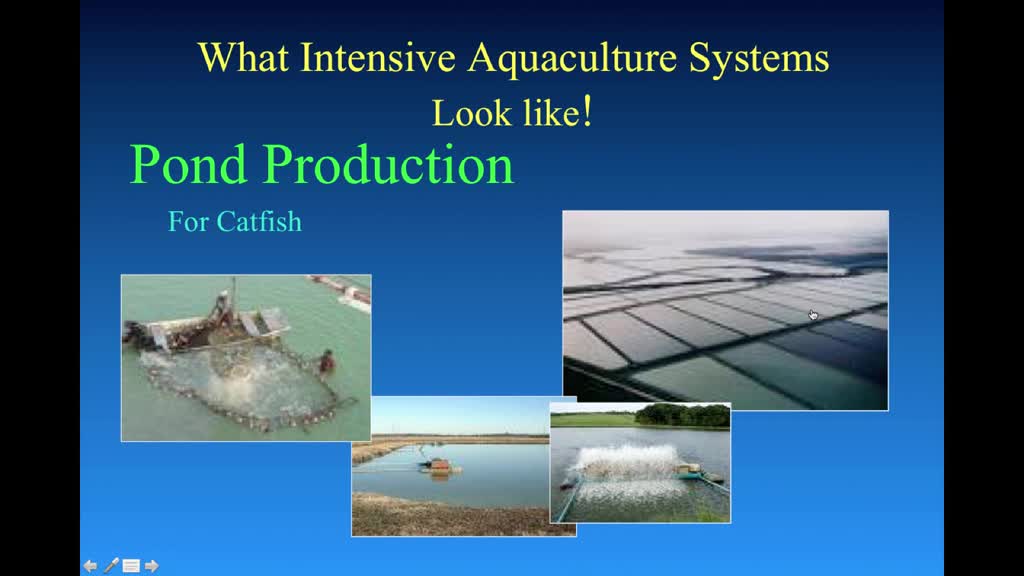

Where are all these fish going to come from, you might ask? Right? Where are they coming from? Okay. This is what most people think of when they think of fishing, you know, where am I going to get the fish to eat for dinner tonight? And they think of a guy standing here, with his fly rod, or whatever, and this huge lake. Well, yeah. Okay. But, here’s a key distinction, between what people perceive, in terms where their seafood is coming from versus reality. The density of fish in such a lake like this, we live next to a lake that’s in the Finger Lakes region, the lake I lived next to Cornell University, is 60 miles long, three or four miles wide, and five or 600 feet deep. And how long does it take to catch a fish out there? Well, to catch one legally sized trout, takes like, 45 hours of fishing. Can you believe that? In other words, it takes forever, because there aren’t hardly any fish out there, and the reason is, because if there were more fish out there, they would all die. Yeah. They would all die because of disease issues. The natural environment is full of vectors, which will contribute to fish disease. You just can’t do, they’re not very dense. But aquaculture, it looks like this. Okay? And look, there’s pretty high densities. Here’s underwater sea cages. These represent raceways. These are intensive ponds. This is rope culture, anyway, very very dense. Okay. Another shot here. Here’s raceways, where the water comes in at one end. These are concrete walls, that divide each raceway. When water comes in at the top, you can see that the water coming in here, goes down through. There’s a fairly rapid exchange of water, to maintain the water quality environment necessary, to support the fish. Another shot of an indoor raceway. Okay. The thing to remember here is that, we have a term called hydraulic retention time, and that’s- if this raceway was totally empty, and I started filling it with water, how long would it take to fill it up? So it was all empty and I filled it up in 35 minutes, we say that has a hydraulic retention time of 35 minutes. Okay? So, it’s what we’ve called turning over every 35 minutes. Raceways typically have a HRT’s that are about 15 minutes, so they turn over very rapidly. And so you can imagine, if I’m turning over this raceway every 15 minutes, it takes huge, I say huge, quantities of water. The other most common thing, we see around the world are ponds. For aquaculture, here’s some munch catfish ponds. These things are typically rectangles. They’re going to be. two-three-five hectares in size, but a very interesting thing here is, you notice how the ponds are all different colors? Well, that’s because they all have different water

environments. So this is not a repeatable or a duplicate set of ponds because the environments are all different, in each one of them. So how are you going to reproduce fish on a repetitive basis? Ponds had a lot of challenges. They also used quite a bit of water just because of evaporation. That’s what I call a mature technology. And at least in the United States, the ability to produce fish on a cost competitive basis with worldwide produce fish, it’s a constraint right now. It’s difficult to do that. A lot of our ponds in South Alabama, Mississippi are being converted actually back into dry land production. So it’s kind of ironic. It went from cotton production, in the 40’s and 50’s, into catfish production in the 60’s, 70’s the 40, 50 years, and now about a third of all that acreage, has been re-purposed back into the dry land culture, soybeans typically. In here, some more of these intensive- this is net pens. So primarily, aquaculture is when these two sources, either raceways, ponds, or net pens. Net Pens have some bad publicity. A lot of bad things are said about them. Most of them not being true, such as they attract sea lice, and then when migrating, salmon swim by, the sea lice go out and attack the migrating salmon. It’s kind of absurd. Also, the net pens, produce a lot of waste material, which they do, it collects on the bottom of the ocean floor, and then has a large pollution source, and degradation of water quality. That could be true, in the case where the net pens, are not sited properly. But the key thing on net pen production is that they are sited, where the tidal exchange of water is large. So the 24-hour cycle, twice a day, you might get 5 to 10-meter changes in elevation in the ocean level, and so that causes a large amount of flushing that occurs. So net pens are- there are also mature technology. Almost 2/3’s of our salmon come from net pen production. Most of the salmon, comes from three areas: Chile, Eastern and Western Canada, and Norway, primarily. And it’s pretty well, equally spread, among those three locations. Then we have Recirculating Aquaculture Systems, and the acronym is what? RAS. So, here’s some examples of indoor, quite nicely done I would say. This actually is a big sturgeon farm. This is actually a raceway configuration; here are round tanks. Here are outdoor tanks. I think this is actually a project we did in Haiti. This is a RAS system.

Slide: 3-PTRRAS001_M1_the-importance-of-sustainability

One question that you need to ask yourself is: how am I going to sell my fish? That should be the number one question always on your head. Well, that means you need to be thinking about sustainability. What’s sustainability all about? Well, this is obviously the, most of you are aware, right? This is a big, hot topic right now for the last several years. And sustainability means a lot, to a lot of different people, but there’s this economic, and environmental, and social interaction. And, I say, there’s a lot going on here, but you need to be thinking about it, okay. And the thing we have going for us, is that we are classified as the most sustainable aquaculture system that is available to producers. So the green, what we call the green people, the environmental groups they all kind of, they kind of recognize that people have to eat food, and if you’re going to eat

food, it’s good if it can come from a sustainable source. And Recirculating Aquaculture Systems, RAS, are definitely sustainable. What is sustainability? Here’s the definition; meeting the needs of the present without compromising the ability of the future generations to meet their own needs. Yes, so that’s kind of the bedrock of that. And this is a little bit dated, 2011, but things haven’t changed much. In menu trends, National Restaurant Association, you can see the things that were moving, seafood. Well, what are they? Locally sourced, locally grown, sustainability, nutritious, nutritious kid’s lunches. Number seven, sustainable seafood. These things are continuing. The big things are locally produced, locally grown, and sustainable. That’s the current buzzwords. Just looking and I’m, here’s a local supermarket and just look at what you’re seeing, right; Wild caught, wild caught, farm raised, wild caught, it seems to indicate that there’s a preference for a wild caught, but things are being labeled. Farm raised, does it- Does farm raised have a good connotation or a bad connotation? Well, most people would view it as positive, but some people will view it as negative. Yeah. Walmart, okay, the big mega group, right. They made a commitment to sustainable seafood by requiring a third-party certification of their suppliers. Okay, so you’re producing a product for Walmart, you’re going to have to go out to get a third- party certification in order to certify you that you are a sustainable source. Seafood Watch, another environmental watchdog defines sustainable seafood as the following: sustainable seafood is from sources or fished or farmed that can maintain or increase production into the long term without jeopardizing the structure or function of affected ecosystems. Product types; farmed, wild seafood, fresh and frozen. There is a seafood certification program by the Marine Stewardship Council. There’s other equivalent groups doing the same thing. Farmed Seafood Certification requires using best aquaculture practices or an equivalent. So you’ll see, groups we’re looking for the Marine Stewardship Council and best aquaculture practices. That’s what we’re looking for, okay? So remember that. If you want to sell your seafood, your aquaculture product, think sustainable.

Slide: 4-PTRRAS001_M1_benefits-of-recirculating-aquaculture-technology

Why do we want to use recirculating aquaculture technology in the first place? Okay, let’s look at some of the reasons. Well, first, I got to tell you why you had to be listening to me. Okay? I’m not just an academic. With my own money and my house on the line, we put up a million pound per year indoor recirculating agriculture production system in Upstate New York, to produce Tilapia. By the way, Tilapia is a tropical species, meaning they need like 28 degrees C 80 degree water. And, Upstate New York is really really cold. Okay, so, recirculating aquaculture. Wow. How could you produce a tropical animal in an upstate cold environment? Well, that’s because we recirculate the water. Here is just a shot of the outdoors. It was about 40,000 square feet. Looks like a big

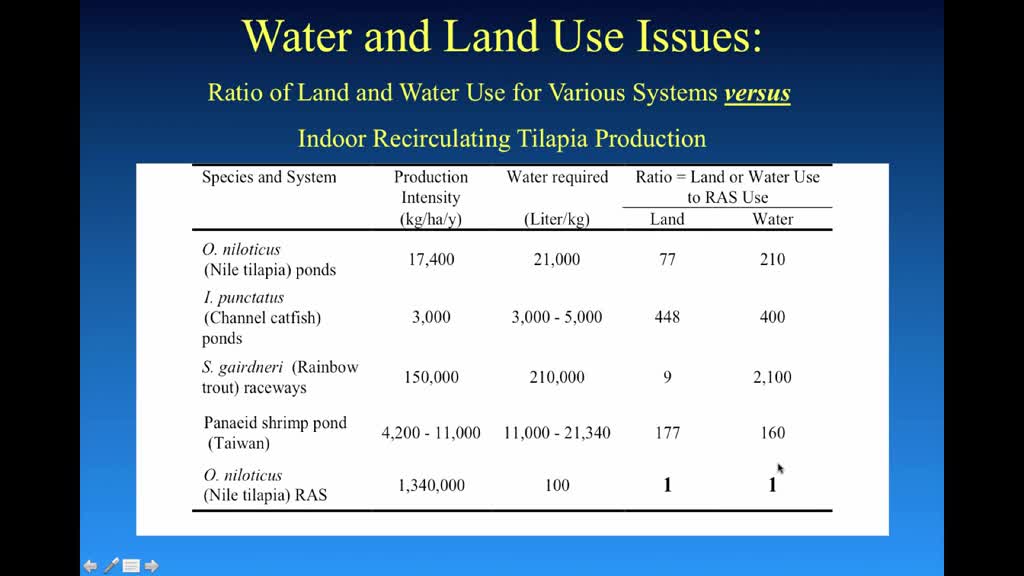

dairy barn and then, here was an inside shot round tank technology, etc, etc. okay. Okay. So, here’s a little bit about Tilapia. That farm was built back in the mid 90s and we actually programed 1996 or 97. And my business plans and such were showing like, Okay, well Tilapia is going to become really big. So, this is a disruptive technology and so, yes invest in me. Okay. Well I couldn’t get any investors. Hardly. So primarily my brother and myself financed this first farm. Anyway, my predictions came true. Producing a lot of Tilapia. Okay, everybody knows it. But back to the point of this video is, why do we reuse water? Well, the whole bunch of reasons, okay? But the primary reasons are, you reuse water so you’re not using this valuable resource. And it’s probably the most valuable resource we have. So, using it to flow through a system that uses huge quantities of water is just not sustainable. The other thing is, is that the less water you use, the less water you have to treat in terms of discharge. Okay, as an EPA and any kind of environmental regulation on what you do with this discharge water. The second big reason is, in a recirculating system, the water that you put into your tanks has to be water that you, yourself, are willing to drink. As in, there’s actually no disease organism being introduced into the water. So, when you do that, the less water you need, the more cost effective you’re going to be. Also, once you’ve started to circulate the water, you can control the temperature very closely. Which means, you can optimize that environment to the animal you’re trying to grow. Minimizing water use deals with bio-security, makes it much easier to control that in terms of keeping disease organisms out. And if you don’t need much water, that means you can put your farm where it needs to be located from a market sense. So, Water Reuse System, there’s three basic types, there’s serial reuse, that means goes down, comes back. We don’t really talk about those, it still uses a lot of water. We’re talking about full re-circulation and this then means you’re talking about something zero, which is almost impossible, but five to 15 or 20 percent water exchanges a day. So, if you had a hundred thousand gallons of water in your farm tanks, 100,000 gallons, that means 15 percent you’d be throwing away 15,000 gallons a day. If you had 100 gallons, you’re throwing away 15 gallons. This is water, this discharged which has to be replaced. It’s not the recycle. This is a reference point back to the Tilapia farm that I showed you earlier. I ran that farm on a hose, doing about 20 gallons per minute. And we circulated 30 million gallons of water a day. 30 million gallons of water a day recycled. I used to raise money with investors, and say, hey, I produced fish with no water. And they go what? No water? I go, well, a little bit. Okay, Well, this slide just kind of shows you that, what I mean by none, okay. So, here’s a big table, here is the steps on your yellow book which you all received and you’re supposed to be reading prior to this lecture. Here’s my Tilapia farm. The ratio is on itself of course is one. Okay. Wow. What if I was doing a raceway? I would use 2000 times more water than I would use in my Tilapia indoor farm. Ponds, somewhere around two to four hundred times more water than I would in my RAS and similar ratios in terms of land use. So, it doesn’t take much land